Connecting Rods

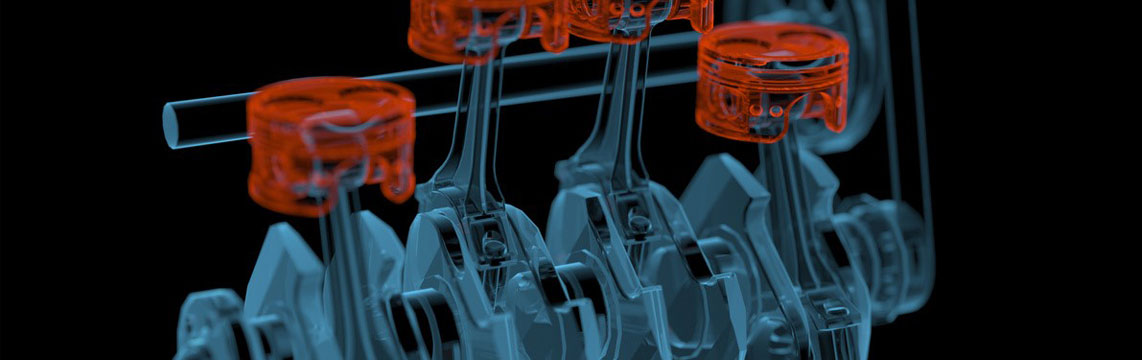

The Conn-Rod is designed to transfer linear motion and energy produced in the combustion chamber into a rotational motion at the crankshaft.

Due to the high stress nature and force needed to rotate the crankshaft and deliver the power, the Conn-Rod needs to be very strong and withstand the immense tensile load as speed increases.

To achieve this the Conn-Rod is mainly forged from a steel alloy known as 4140H. This type of alloy is used in various industries that need to withstand high pressure and repeated stress, it also allows for superior machining capabilities.

Fracture split Conrods however use a different approach, various permutations of steels that can be split are used. This method holds many benefits within the manufacturing process and imparts cost reductions.

The benefits from a manufacturing perspective would be the speed in which the Conrods can be produced, instead of machining joint faces and using dowel pins for location, a fracture split is quite literally split in the middle of the large end bore using tremendous force, producing a unique pairing face with no need for joint face milling or dowel pins, because this is a quicker process the costs can be passed on to the customer.

Along with fracture splitting there are several other possible strategies to enhance the Conn-Rod.

Bushless Conrods are a comparatively new design that benefits from not inserting a bush into the small end, instead a coating of manganese phosphate is applied to the steel bore. This coating provides a key for lubrication to create a film between mating running surfaces. This technique results in a cost saving as there is no bush used, it also has an environmental benefit as the coating does not break down into ash and expelled into the environment.

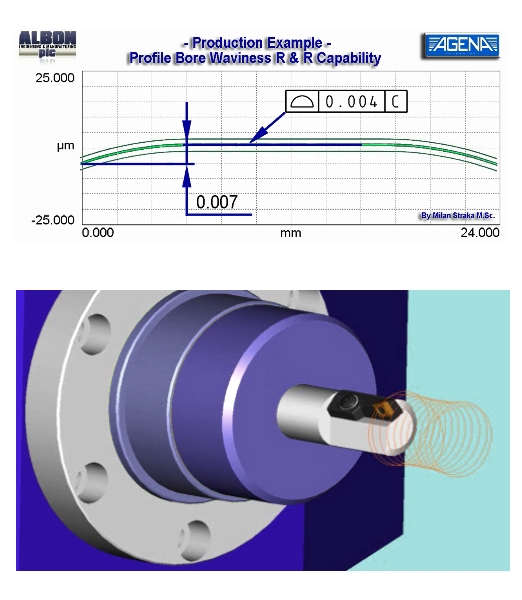

Trumpet boring the small end or pin bore of the Conn-Rod involves intentionally machining a contour that allows a reduction in the piston pin load, improved lubrication and possible damage prevention under load.

Oval boring has a similar effect focusing on reducing the stresses on the piston pin after ignition at top dead centre, post pin bore distortion. The distortion over repeated stresses creates a flat on the piston pin that could cause unwanted friction.

Burnishing the bush after insertion into the small end parent bore increases mating surface textures resulting in an increased surface percentage contact, sometimes measured as a surface contour known as RMR, the better the contact between these two elements the better the emission control and connecting rod quality.

VCR or variable compression ratio is the ability to adjust the compression ratio of the internal combustion engine whilst in operation, the variable compression allows the volume of fuel at piston top dead centre to be changed therefore imparting a more efficient and cost-effective burn. Alongside the engine running cost reductions of implementing VCR technologies there is also the environmental benefits to be gained from greater fuel efficiency, meaning the increasingly stringent emission laws are complied with and exceeded.

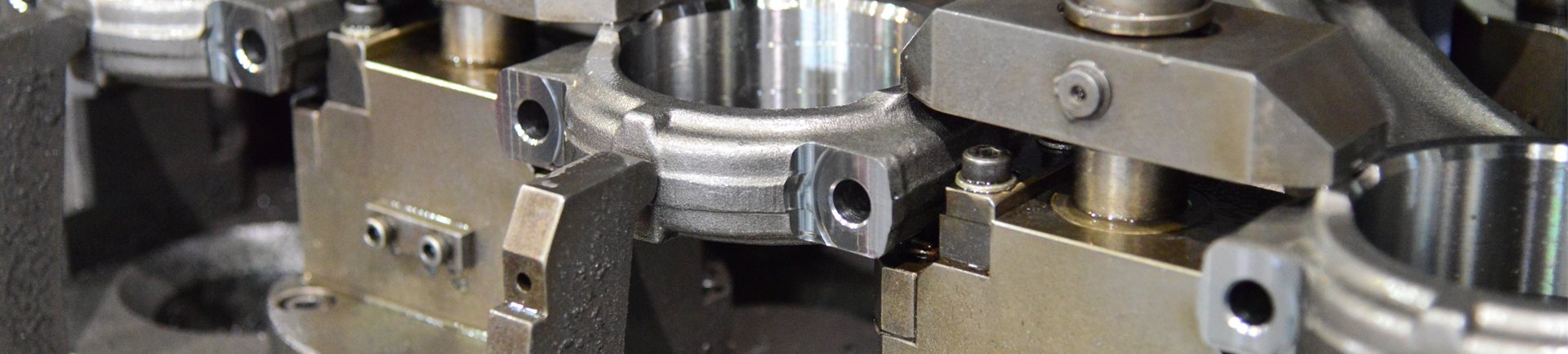

Albon Engineering & Manufacturing is proud to have been involved in pioneering technologies throughout the Conn-Rod manufacturing processes since it’s conception in 1970 and strives to achieve optimal results using its vast knowledge of this complicated and vital engine component.

One of Albon’s success stories

Mercury Marine wanted three different connecting rods which they would like us to manufacture. This would have potentially caused a lot of our competitors a problem as they wanted all three manufacturing lines installed from initial discussion to full production within 4 months.

Albon engineering’s advantage and solution is to keep as much production, manufacturing, design & engineering as in-house as possible. This reduces lead time going into production.

Want to find out more? Feel free to get in touch and one of our friendly team members will get back to you shortly.